Results 1 to 8 of 8

Thread: Dura-cote

-

February 17th, 2009, 09:39 PM #1

Dura-cote

Dura-cote

Hello All

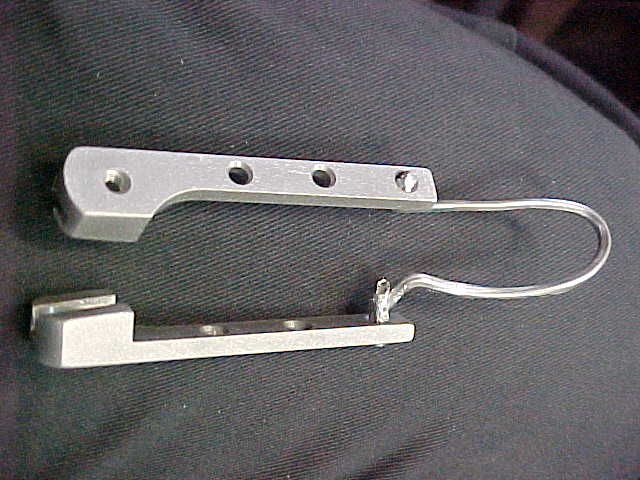

I have some anodized parts (but not dyed) for my new AR build.

I was thinking about dura-cote since they are still in the white.

Any opinions or suggestions as to who does a good job.

Here are the parts I want to coat

Thanks

An OC Activist

EdLast edited by edstephan; February 19th, 2009 at 12:03 AM.

FeedBack: https://forum.pafoa.org/showthread.p...ight=edstephan

An OathKeeper and OC Activist, 1 of the 3%, Ed Stephan

-

February 18th, 2009, 07:38 PM #2

Re: Dura-cote

Re: Dura-cote

You can do it yourself and get the satisfaction of knowing you did it yourself.

I personally do not like Duracoat...it's not very durable and it can take up to 4-5 weeks to fully cure.

If it was my firearm, I would go with a thermal cure finish such as Norrell's Moly Resin or KG Gunkote. Because they are baked...those two finishes are much more durable compared to Duracoat.

Duracoat's advantage is it offers a multitude of colors and camo patterns.

-

February 18th, 2009, 07:51 PM #3

Member

Member

- Join Date

- Apr 2008

- Location

-

Greentree,

Pennsylvania

(Allegheny County) - Posts

- 76

- Rep Power

- 18

Re: Dura-cote

Re: Dura-cote

I posted the below in the gunsmithing forum, but got not much response. The response above is kinda what I was looking for. Can anyone else give any direction?

I just had three milled Yugo AKs (2 folder, 1 fixed) rewelded professionally. The guy who did them did a beautiful job, however, I did not pay to have them finished as well.

I need advice on a do it yourself gun finish that is easy to apply and will be durable. I am not making these into trophies, they will be shooters.

Some options I am considering are:

GunKote: http://www.midwayusa.com/viewproduct...tnumber=853121

Duracoat: http://www.midwayusa.com/viewproduct...tnumber=711180

DuraBake: http://www.midwayusa.com/viewproduct...tnumber=598223

Parkerizing: http://www.midwayusa.com/viewproduct...tnumber=731489

I would appreciate any feedback from anyone who has used any of these products. Also, if there are additional supplies nescessary that aren't included in those links, let me know so I can calculate total cost. For instance, I know the GunKote needs an airbrush, and Parkerizing needs some type of tank (not sure what material it needs to be).

Thanks for the help.

-

February 18th, 2009, 08:09 PM #4

Re: Dura-cote

Re: Dura-cote

Brownell's also has the Alumahide which comes in a rattle can.

-

February 18th, 2009, 11:01 PM #5

Re: Dura-cote

Re: Dura-cote

To get the very best finish, you want to have the parts anodized or better yet park'd. Those two finishes will help bond to the thermal cured products such as Norrell's and KG Gunkote.

You will need to take your time with the prep work...degreasing is a must for thermal cured.

You can buy an inexpensive air brush kit from walmart....they also sell the cans of air as well.

You can heat up your parts and spray on the finish...if the parts are heated...they will basically dry to the touch. You will need to bake the parts in an oven. Make sure your oven temp is correct...most thermals require 1 hour at 300 degrees. Once the parts cool, you are ready to use the parts.

The finishes go on thin, so make sure you do 2-3 coats, especially around wear areas IE on an AR15, brass deflector and around the mag well.

I'd show you some pictures, but I cannot find the image hosting on this forum anymore.

ETA: I had these on another site

Norrell's in OD

KG Gunkote...the flashilight and mag were done in KG.

Last edited by aubie515; February 18th, 2009 at 11:05 PM.

-

February 18th, 2009, 11:05 PM #6

Re: Dura-cote

Re: Dura-cote

having just done a GLOCK and AR in duracoat I would say don't do it if you need it to last and care about it, if its a kickaround gun, OK but I do not depend on Duracoat.

How pissed are you gonna be if you die before the Zombie Apocalypse comes? - - IANAL

-

February 19th, 2009, 12:09 AM #7

Re: Dura-cote

Re: Dura-cote

What about Brownells Teflon/Moly Gun Finish or Brownells GUN-KOTE?

I'm not very good at painting or finish work and want these to look good.

I posted pictures of the parts on OP.

They are already anodized.

An OC Activist

EdFeedBack: https://forum.pafoa.org/showthread.p...ight=edstephan

An OathKeeper and OC Activist, 1 of the 3%, Ed Stephan

-

February 19th, 2009, 12:20 AM #8

Super Member

Super Member

- Join Date

- Sep 2006

- Location

-

Tannersville,

Pennsylvania

(Monroe County) - Age

- 56

- Posts

- 749

- Rep Power

- 142

Re: Dura-cote

Re: Dura-cote

Both Gun-Kote and bake on Teflon/Moly work great as long as you properly prep the items to be coated first. I have used Gun-Kote on about 40 different Glocks and S&W's now and the best way I found was to bead blast the parts with red oxide first. The red oxide leaves a rough finish comparable to the finish on a park'd firearm and really gives the finish something to bite onto to. I tried doing a Glock slide without hitting it with red oxide first and the finish pealed off the Tenifer coating with the first application of Gun scrubber. On the other hand, Glocks that I red oxided first are still holding up like they were done yesterday and a few of them were done 5 years ago.

Rich W.

Similar Threads

-

DURA COAT

By Michele in forum GeneralReplies: 30Last Post: November 28th, 2007, 08:37 AM

Reply With Quote

Reply With Quote

Bookmarks